Cartridge Heaters

The team here at Hedin Heaters are experts in all types of electrical heating products, but have a particular specialism in cartridge heaters. We provide specialist cartridge heaters for customers across the world, and our expert team is able to supply you with industry-leading advice to ensure you receive a product that perfectly aligns with your requirements.

Highly sought after in the plastics and process industry, we work with a variety of clients ensuring they receive quality cartridge heaters that are perfect for:

- Moulds and Dies

- Packaging

- Tooling

- Platens

- Rollers

- Refrigeration

- Smelting

- Fluidic Heating

- Heat Welding

- and many more

Our cartridge heaters are very rugged, with a high watts density, swaged in construction and hi-temp, which means they can achieve a standard maximum temperature of 750°C.

Available in single or three phase, with graded heat distribution or built-in thermocouples, all our cartridge heaters are UKCA or CE approved, with UL certified heaters also available (please ask our team for more information).

Square, split-sheath, finned, IP67, PTC and Immersion cartridge heaters are also available.

Cartridge Heater Construction

A Nickel-Chromium 80/20 heater wire wound around (for high watts density) or run through (for medium and low watts density) a hard ceramic core forms the basis of a cartridge heater. This wire is connected to a conductor lead and the assembly is then inserted into a metal sheath with one end closed and the core insulated with magnesium oxide. The end of the sheath where the wires exit is sealed using ceramic beads and the entire assembly is swaged to reduce its size. Once reduced, the heater will be terminated and any lead protections and mountings added.

The resistor core (made up of a resistance wire and a ceramic core) is assembled accurately and consistently spaced close to the outer sheath for efficient heat transfer. The swaging reduces the diameter while increasing the density and minimising air gaps. This results in a heater with good dielectric strength and efficient heat transfer characteristics.

The Watts Density of Cartridge Heaters

The watts density of a cartridge heater determines what temperature it can reach. We can supply low, medium or high watts density cartridge heaters with each having different benefits.

Low Watts Density

For temperatures up to 350°C, use a low watts density cartridge heater. These heaters will not exceed a heat intensity of 4W/cm². The heater wire for this type of cartridge goes through the ceramic core a number of times rather than being wound around it. These heaters come in standard sizes, with a minimum diameter of 6.35mm and a maximum of 60mm, making them more cost effective. And because of their lower temperature ceiling, they can be safely left running for long periods without risk of overheating. Their large maximum diameter means they can be used in places where larger bodies require heating.

Medium Watts Density

For temperatures up to 600°C, use a medium watts density cartridge heater. These heaters will have a heat intensity that does not exceed 10W/cm². The heater wire for this type of cartridge goes through the ceramic core a number of times rather than being wound around it. These heaters come in standard sizes, with a minimum diameter of 3.1 mm and a maximum of 32mm. Because they can reach higher temperatures with a smaller diameter, medium density cartridge heaters can be used in situations where the larger low watts density heaters aren’t suitable.

High Watts Density

For temperatures up to 750°C, use a high watts density cartridge heater. These heaters will have a heat intensity not exceeding 40W/cm². The ceramic core has the heater wire wound around it rather than going through it. High watts density heaters are bespoke heaters with the size, wattage and voltage tailored to the user’s requirements. Under special circumstances, we can supply heaters with a heat intensity of 50W/cm² and temperatures up to 870°C.

Cartridge Heater Dimensions

We can make bespoke high watts density cartridge heats in any size, imperial or metric, in the following ranges:

- Diameter: 3mm to 32mm (but up to 60mm in special circumstances)

- Length: 20mm to 6000mm

Our heaters are made to tight H7 dimensional tolerances.

Cartridge Heater Materials

We can make the sheathes of the heaters from the following materials:

- Incoloy 800

- Stainless Steel 304

- Stainless Steel 316

- Stainless Steel 321

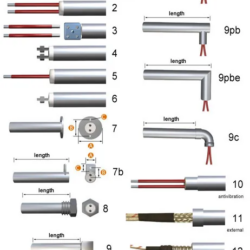

Cartridge Heaters Terminations and Lead Protection

Depth location can be provided via circlips cut into any circular cartridge heater. We can supply earth wires on all cartridge heaters on request. Examples of the terminations available are as follows:

- Internally connected leads

- Square lock armour

- Externally connected leaders

- 90° leads with stainless steel leaders

- Braid over pairs of leads

- 90° leads with stainless steel armour

- BSPP, BSPT or NPT bushing

- Straight leads with clip support

- Right angle elbow

- Right angle with clip support

Lead Protection:

The choice of connecting leads and cabling is very important. From shocks, vibrations and sudden excessive movements, to the avoidance of scratches, cuts and breakages as well as different environmental situations like excessive heating, moisture, and corrosive fluids, there is plenty to consider when making the choice.

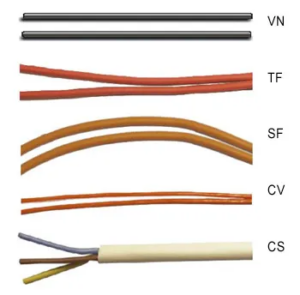

Options include:

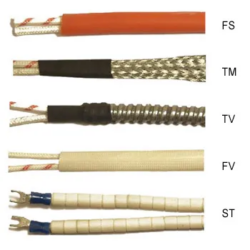

- Lead Wire Cabling Sleeving

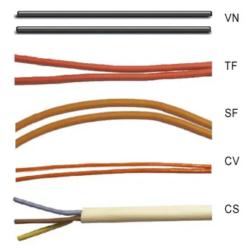

- Rigid Nickel Rods (VN)

- Silicone Sleeve (FS)

- Teflon (TF)

- Twisted Mesh/Braided Metal (TM)

- Flexible Silicone Lead (SF)

- Nickel Vinkel Hose (TV) or Galvanised Steel Armour

- Glass Fibre Lead (CV)

- Fibre Glass Sleeve FV)

- 3-Core Silicone Tube (CS)

- Steatite Beads (ST)

The Types of Cartridge Heaters

Square Cartridge Heaters

Square cartridge heaters are uniquely suited to situations when quick adaptation in moulds is required, or on surfaces where the use of rivets causes problems using standard cylindrical cartridges.

Square cartridge heaters are uniquely suited to situations when quick adaptation in moulds is required, or on surfaces where the use of rivets causes problems using standard cylindrical cartridges.

They come in the following sizes:

- 9.5mm (3/8″)

- 12.7mm (1/2″)

- 10mm

- 15mm

- 12mm

- 15.9mm (5/8″)

These are cartridges with a low wattage, as such they are most suitable for moderate heating up to a maximum temperature of 300ºC.

The square sheath is made of stainless steel. This can stand up to continuous temperature variation and has the best possible thermic conductivity, as the ceramic piece is in contact with the wall of the tube, which makes for near-perfect distribution of heat.

Split-Sheath Cartridge Heaters

The expandable (split sheath) cartridge heater solves two major problems with conventional high-density compressed heaters, heat transfer due to an inadequate fit and difficulty with extraction, thereby improving the accuracy of the temperature and the longevity of the equipment.

The expandable (split sheath) cartridge heater solves two major problems with conventional high-density compressed heaters, heat transfer due to an inadequate fit and difficulty with extraction, thereby improving the accuracy of the temperature and the longevity of the equipment.

When put into a hole and turned on, split-sheath heaters expand to fit. This is ideal for larger holes and for those that are a loose fit due to wear and tear or having been drilled out.

They support faster and easier extraction, as split sheath cartridges close together when cool, reducing the diameter and loosening the fit within the hole. Consequentially there is no need for drilling out the cartridge or using lubricants which saves a lot of time and effort.

This allows for trouble-free use in longer holes, as the split sheath design increases the cartridge’s rigidity and prevents bending, therefore keeping a flatter profile and enabling a better fit. Due to the split sheath expanding and contracting its diameter, there is less need to worry about tight tolerances i.e. a loose fitting or drilled-out hole.

Both standard sizes or customised versions to your specifications are available.

Additional benefits include:

- Longer lifespan

- More compact terminations

- Easy removal

- More drill tolerance

- No cold zones

- Many different terminations

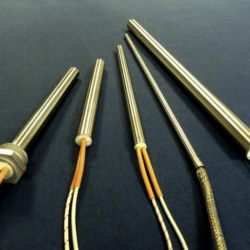

Cartridge Heaters with inbuilt Thermocouple

The majority of cartridge heaters can have an inbuilt thermocouple temperature sensor with the only requirement being that the element is big enough to fit the thermocouple within it. You can install a thermocouple in one of two ways:

The majority of cartridge heaters can have an inbuilt thermocouple temperature sensor with the only requirement being that the element is big enough to fit the thermocouple within it. You can install a thermocouple in one of two ways:

- Isolated – Not in contact with the sheath which reduces signal noise.

- Grounded – Connected to the sheath at either the top, middle or bottom of the heater so its exact location is known.

These heaters have several advantages over a standard cartridge heater including:

- Longer lifespan

- More accurate temperature control

- Energy saving

- No Need for an additional sensor

For lower temperatures, we would use a Type J thermocouple.

For higher temperatures or damp/corrosive environments, we would use a Type K thermocouple.

Finned Cartridge Heaters

For air heating applications, a large surface area is desirable for efficient heat transfer. We can supply finned cartridge heats to suit your needs.

For air heating applications, a large surface area is desirable for efficient heat transfer. We can supply finned cartridge heats to suit your needs.

These are only available in a diameter of 9.5mm (3/8″) with 23.8mm (15/16″) diameter fins.

Immersion Cartridge Heaters

When you need to heat oil, water or other fluids, then an immersion cartridge heater would be a good option. They come with moisture/water-resistant seals and are suitable for prolonged immersion. Termination boxes are available. Typically these have a BSP or NPT boss, although we can accommodate other thread sizes if required.

When you need to heat oil, water or other fluids, then an immersion cartridge heater would be a good option. They come with moisture/water-resistant seals and are suitable for prolonged immersion. Termination boxes are available. Typically these have a BSP or NPT boss, although we can accommodate other thread sizes if required.

These heaters are ideal for when a rod element immersion heater is too large for the environment.

PTC Cartridge Heaters

PTC (Positive Temperature Coefficient) cartridge heaters eschew the resistance wire in/around a ceramic block in favour of a ceramic semiconductor. This increases in resistance as its temperature rises and is separated from the sheath by a layer of compressed magnesium oxide.

PTC (Positive Temperature Coefficient) cartridge heaters eschew the resistance wire in/around a ceramic block in favour of a ceramic semiconductor. This increases in resistance as its temperature rises and is separated from the sheath by a layer of compressed magnesium oxide.

As the temperature increases so does the resistance, while the power absorption decreases. These types of heaters don’t require overheating safety systems.

PTC heaters are medium density with a maximum temperature of 220°C. As such, they are ideal for anti-condensation applications or industrial refrigeration.

Technical Expertise in Cartridge Heaters

Our team has spent over 80 years supplying heaters to customers across the world, and our technical expertise is second to none. We train our technicians to the highest possible level, and regularly produce large quantities of cartridge heaters at competitive prices.

Cartridge heaters have been part of our product range since the 1930s and remain one of our most popular products. Over the years, they’ve remained at the forefront of our business.

We can easily reproduce cartridges that we’ve made before. There is often a marking of ‘RHL’ on older cartridges, so please quote this reference number in your enquiry and we’ll know exactly what you need. If no reference numbers are present or legible, give us a call and we’ll take the necessary details to enable us to design and manufacture direct replacements.

We also offer express breakdown services for urgent requirements.

If you need any more information, please contact our team. Simply give us a call or complete our online form and we’ll be in touch to discuss your requirements with you.