Electric Duct Heaters

At Hedin Heaters, we have spent over 80 years supplying customers around the world with quality heating elements and components. This includes electric duct heaters that play a fundamental role in many industries and applications.

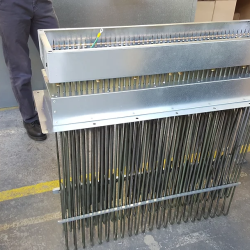

The purpose of an electric duct heater is to heat air (and other non-flammable gases) to a desired temperature. Electric ducted heaters are the most common of this type and operate by creating an electric current through metal elements that then generate heat. Square, rectangular or circular are the standard forms in duct heater manufacture. Incoloy or stainless steel rod elements are used within heater cases constructed of galvanised or stainless steel. The cases are made robustly and can be fitted with mounting flanges at both ends to facilitate installation into customers’ ducting.

Our team draws on decades of technical knowledge to manufacture products that are sturdy, reliable and can be manufactured to the unique specifications of all our customers’ requirements.

As well as our standard duct heaters, the team at Hedin Heaters can also supply you with stab-in heaters if you require them. These are made from standard terminal boxes and supplied without duct casing.

To protect the heater from airflow failure, automatic and manual reset cut-outs are supplied on all ducted air heaters as standard additionally, auto-reset cut-outs and pressure sensors are also available.

Furthermore, a variety of optional extras are also available such as integral thyristor control, silencers, mesh wire and powder coating and we can supply independent additional control panels when required.

Electric Duct Heater Construction

A duct heater generally consists of a number of rod elements, sized for the particular application and mounted in a standard ISO-sized duct.

Galvanised or stainless steel forms the duct casing with an airtight seam.

The terminal box has knockouts for power and signal inputs.

Standard features include a failsafe overheat cut-out.

Duct Heater Site Requirements

The heater will require a mains isolator located adjacent to it and will need to be wired in series with the fan.

If you are providing your own controls, you need to allow for an air-proving switch and a suitable power relay.

Features of Electric Duct Heaters

Features and options for our duct heaters:

- Temperature classification (eg T3 classification up to 200°C max)

- ATEX duct heaters

- Ideal air velocity 2.0m/s (minimum 1.5m/s)

- Manual reset cut-out

- Auto reset cut-out

- Flanges (undrilled, drilled, mez type)

- Pressure sensors

- Integral thyristor control

- Powder coating

- Mesh wire

- Additional control panels

- Silencers

- Staged/Stepped

- Lifting lugs

- Earth bolts

Duct Heater Materials

We can make the ductwork of the heaters from the following materials:

- Galvanised steel

- Stainless steel 304

- Stainless steel 316

We can make the heating elements from the following materials:

- Incoloy 600, 800, 825

- Mild steel

- Stainless steel 304, 316, and 321

- Copper

- Titanium

- Teflon

Tyes of Electric Duct Heaters

Stab In Duct Heaters

When it’s impractical to remove a section of ducting or to install a full duct heater, stab-in heaters are the solution.

A suitable hole will be cut in the side of a duct to mount a standard terminal box, with rod elements inside it, to make stab-in heaters.

Our heaters are fitted with a thermal cut-out, which protects them from airflow failure and once the fault has been rectified the thermal cut-out can be manually reset.

Electric Duct Heaters with inbuilt Controls

The customers’ existing system can control the heater or our heaters can include built-in controls if required.

Basic controls:

- Temperature controls

- Safety controls

Full Feature Controls:

- Thyristor ‘pulse’ control and set point

- DTFS combined airflow & temperature sensor

- Fused fan outputs

- Off delay timer

- Remote start/stop

- Fault signal

- Various inputs

ATEX Duct Heaters

Certified to the required standard, we can supply hazardous area ATEX/IECEx approved duct heaters.

ATEX Heaters are ideal for potentially hazardous (explosive) atmospheres.

Our ATEX flameproof heaters reduce the risk of ignition, by containing sparks and electrical arcing within the terminal box.

Staged & Stepped Duct Heaters

Duct heaters can be designed with various stages or steps. They separate the heating elements into banks and pass the air over them consecutively. Once the system reaches the desired temperature, it turns off some elements to conserve energy. The still-operational elements maintain the temperature.

The user can also carefully control the temperature ramp-up rate using controls, which is useful in applications such as curing ovens where we do not want the heated area to get too hot too quickly.

Air pressure will decrease as the air passes over each of the elements. We can use finned elements to increase the surface area and reduce the length of the duct heater, thus reducing the pressure drop.

Delivering Electric Duct Heaters Across the World

Our team has spent over 80 years supplying a range of heaters to customers across the world, including electric mat heaters, band heaters, cartridge heaters and duct heaters. Our technical expertise is second to none and we train our technicians to the highest possible level and regularly produce duct heaters for any application at competitive prices.

If you need any more information, please contact our team. Simply give us a call or complete our online form and we’ll be in touch to discuss your requirements with you.